Walnut Headphone Stand and Audio Case

A past client reached out and asked if I could commission and build a headphone stand and case for some desk top audio equipment.

She sent over some pictures for inspiration and gave some basic direction for the scope of work.

“ I don't really have anything exact in mind. The only thing I really need is for the stand to hold the headphones in a way so the ear pads don't get crushed. So preferably they'll hang by the headband. Besides that, I'll leave everything else up to you.”

” feel free to make this as simple or complex as you'd like, or whatever is easiest/best for you or whatever you feel inspired to do.”

Anybody who knows me personally, knows this creative freedom is like opening Pandora’s box.

When a client gives free creative freedom, these are the projects that really energize me and keep me up at night. For me this is the crossover from maker to artist. This is truly the biggest compliment, the client trusts me enough to design, create, and build them a completely custom project.

My initial design with this headphone stand was to go the complicated route and incorporate a couple types of joinery. I sketched out a design and found some thicker pieces of cherry. I was going to use bridal joints for the “arms” and a bigger sliding dovetail to connect the “arms” to the base. After cutting some of the joints, something was just out of joint (yes, pun intended ;) ). I could see where the idea was going but it was just off. The pieces were going to end up in the burn pile, instead they went to the spare parts bin.

As much as complex and complicated seemed like the direction I wanted to go. Simple and clean was the destination. To me there was more with having less going on.

After seeing a lamp online now with another working idea, I went to the local hardwood store and picked out some pieces of walnut. I am no woodworking purist and I believe there is room for both technology and hand tools in the shop. Using Fusion 360 to design the vertical piece I was able to visualize and change my design without making firewood. After coming up with a design that felt right, I took the design to my shop helper C+C Creative Factory (my CNC machine for those that don’t get the reference).

What came out was beautiful. A little bit of hand tool work, and my vision was coming to live. The base and the “arm” both were designed with some scraps in the wood till their shape was refined then I could transfer that image to the walnut.

Finally the finished product was coming together. I have been experimenting with finishing and I ended up sanding to 800 grit using tung oil, shellac, and a wax finish. The result was a finish that begged to be touched.

The next item on the list was a desk top audio case that was to hold a small headphone amp and in-ear monitors. The design process started again.

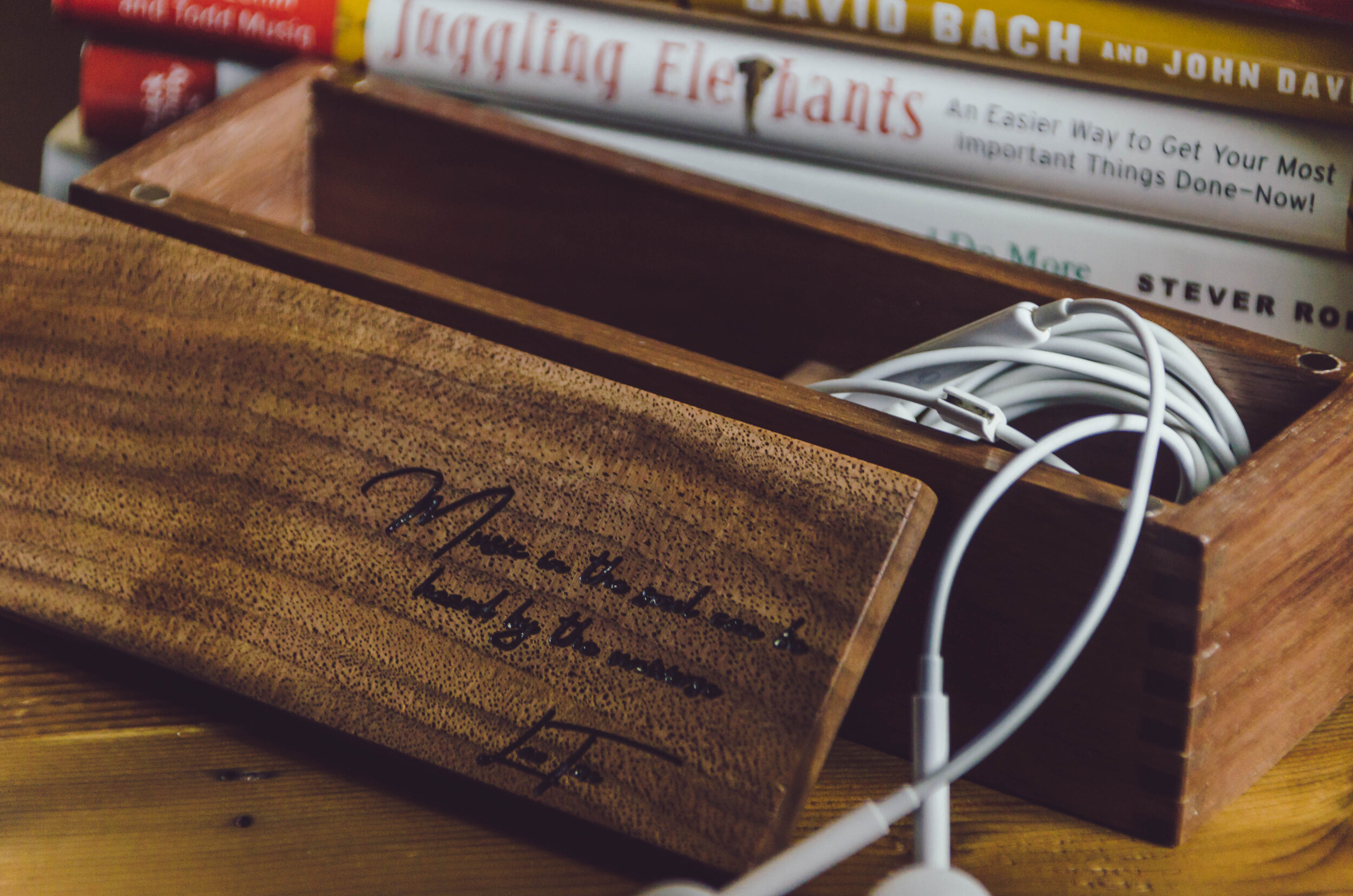

To match the headphone stand, I used more walnut. The case was constructed with box joints, and the interior divider was fitted with the smallest mortises I have made to date.

I asked the client for some favorite quotes and “Music in the soul can be heard by the universe (Lao Tzu)” was engraved on the lid. The lid is secured with magnets to hold the lid on tight.

The desktop audio box was finished using the same technique I used on the headphone stand with the same silky smooth result.

As the project progressed I kept in contact with the client to get feedback and to let her know how the progress was progressing. I really this is important to make sure my design is heading in the right direction, and to let the client see the project come together.

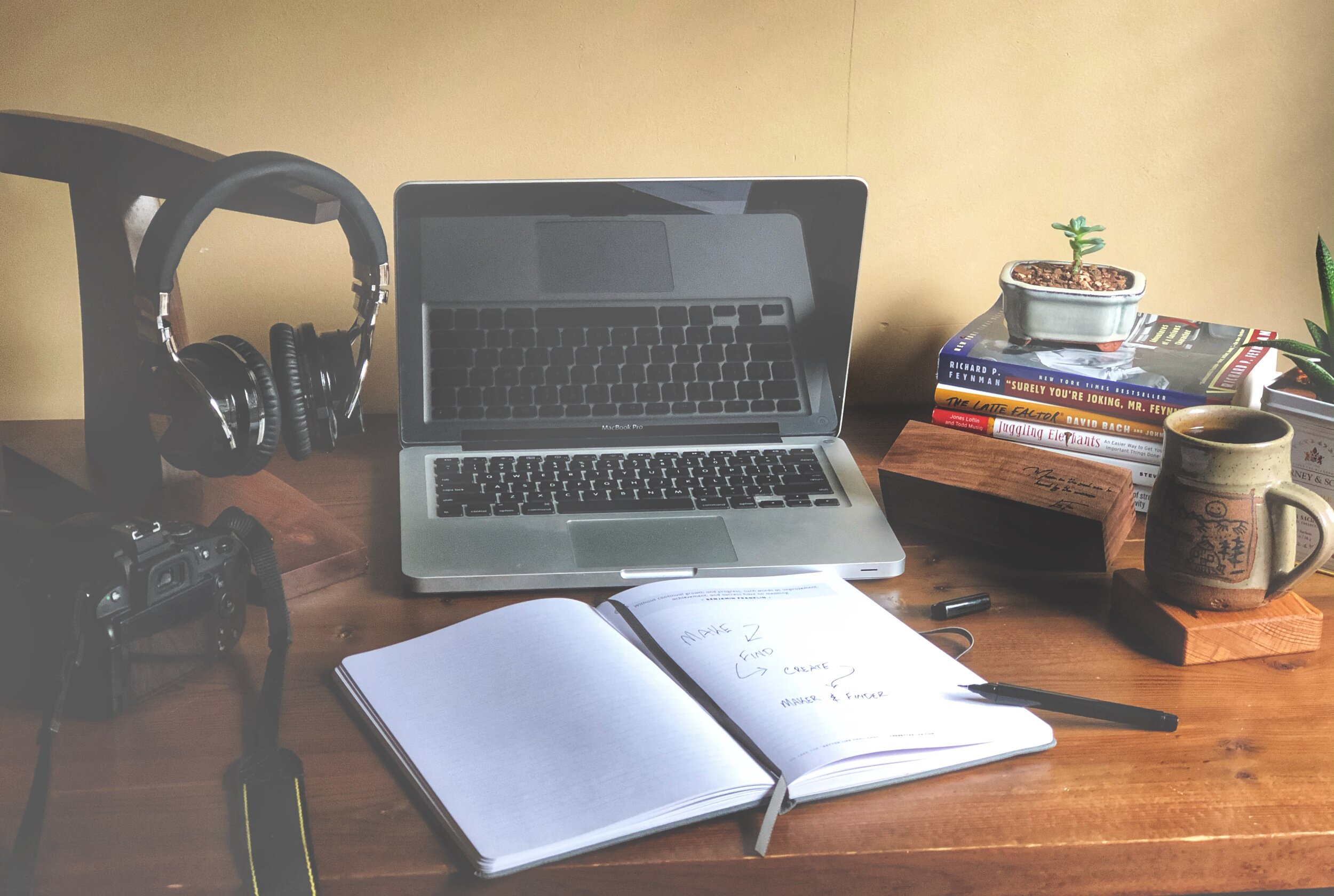

When it was all finished I staged the items for some glamour shots and then it was time to head to the shipping department. Each piece was wrapped in bubble wrap and wrapped in some special wrapping paper for some built in anticipation when the package arrived.

In the end the client loved the headphone stand and desktop audio equipment. I really do try to take into account every detail from the design, communication, pictures, and packaging because my clients aren’t just buying a product but I hope they have a great experience. To me that is what makes custom work so special.